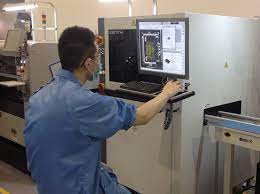

What Is an Automated Optical Inspection System?

The increase in demand for consumer- grade factors is constantly on the rise, thanks to the fast-paced elaboration of the electronics assiduity. As consumer norms for bias ranging from simple calculators to the rearmost smartphones and other electronic bias go higher, companies in the electronics manufacturing assiduity are pressured not just to make further factors, but also to insure that the increased product doesn’t affect the quality of each product. Automated optic examination (AOI) systems have helped manufacturers keep up with the demand for quality and volume.

High-tech Eyes for High-tech Production

An automated optic examination system comprises one or further cameras designed to check products, generally during colorful phases of the product process. AOIs are generally used to check the quality of published circuit boards, transistors, and other factors where indeed the fewest disfigurement can lead to serious problems.

Cameras are designed to descry crimes with perimeters of error typically indiscernible to mortal inspectors. This is made possible by having the cameras compare what they can overlook to finely-calibrated base values of variables needed to pass productstandards.However, the system sends a announcement, product can be stopped, If any of the variables go beyond the respectable limit.

Cameras used in AOI may have a limited field of view, and moving servers of PCBs to align with the cameras bear a lot of space to give the charger enough room to move every piece into position. This is why moment’s AOI systems move the cameras rather. A series of finely-tuned XYZ tables powered by important assiduity- grade factors allow cameras to be dislocated both horizontally and vertically. As with the cameras themselves, these factors can be programmed to move with extreme perfection to make sure the cameras are always in the right place.

The Benefits of Efficient Automated Inspection

There’s no denying that AOI results have helped innumerous companies survive and indeed thrive in the electronics manufacturing assiduity. A near a look at some of its benefits help exfoliate light as to why businesses of every scale and size should prioritize the integration of AOI in their product process.

Cost- slice – Coffers needed to address problems late during the product process can fluently restate to huge losses. This is indeed worse if a batch of blights slip once examination and force a company to issue product recalls latterly on. Because an AOI system can check for blights indeed at the foremost corridor of the product process, companies have multiple chances of detecting blights at stages where fixing them is fairly cheaper.

More QA – As with any automated system, one of the biggest advantages of AOIs over homemade examinations is the lesser degree of perfection when checking for problems. In discrepancy, homemade examinations are prone to missing out blights that would ’ve been egregious under a camera.

Quick, Nonstop Product – AOI systems can be programmed to check batches of products at a important faster rate than what an entire platoon of mortal inspectors would be suitable to handle. Also, AOI systems witness veritably little time-out, thanks to assiduity- grade corridor designed to operatenon-stop. In case commodity goes wrong with an AOI system, corridor can snappily be replaced.

With so numerous benefits they can give, it’s surprising that AOI systems are still substantially used for checking the quality of PCBs and other electronic factors. Still, numerous are hoping that it’s only a matter of time before the technology is espoused by businesses in other diligence. With the development of more effective, protean, and affordable systems, AOI may soon come the norm in quality assurance for anything that involves manufacturing.